Design Challenge

#1: How might we keep our communities in Singapore safe and healthy during the global COVID-19 pandemic?

Project Description

With the COVID-19 showing some signs of abating, we can’t be complacent about personal hygiene and what you touch in public. And door handles in general, apparently, are a hotbed of pathogens which can transmit diseases. It’s said that Coronavirus can be present on surfaces for a long period of time.

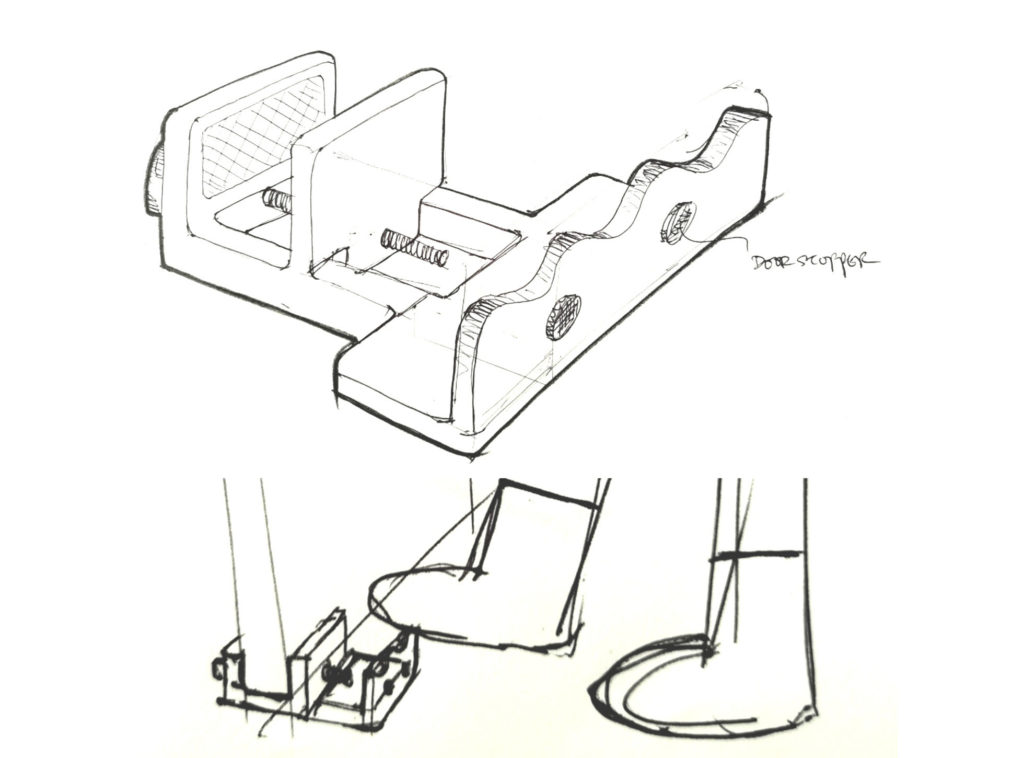

Foot door clamp’s primary objective is to prevent hand contact to door handle.

Its secondary functions including serving as a functional door stopper, potential design exploration for creativity from minimalist to quirky design and a functional product for use even Post-COVID.

Criteria #1: Value

This idea is a replacement for traditional door handles that reduces the risk of spreading germs and contagious diseases by refraining hand contact with contaminated door handles in domestic or public areas.

The design can be potentially looking like a minimalist 3M hook or a quirky lifestyle product to inject some “fun” within interior spaces.

I am still exploring how it can also be a door stopper to encourage people to open up their residential door.

Criteria #2: Inspiration

There are existing products in the market, but it requires drilling of doors during installation which is recommended for high frequency usage for durability. My concept is to focus on enhancing a relevant product that is already out in the market and combining it with F-clamp idea for convenient installation.

Criteria #3: Impact

I think about innovation with product design that is practical and suitable for use across different user groups. While there are great digital product ideas, physical product design brings sustainability towards influencing habits, physical reminder and functionality.

This concept is suitable for low cost mass production for domestic/commercial use with partners such as 3M or Ikea.

Criteria #4: Timeliness

With the help of industry experts, taking inspiration from F-clamp mechanism, research dimensions of doors and material for production could possibly take up to 1-2 months.

With the help of a CAD engineer, I believe I can prototype using 3-D printing within stipulated time.

Criteria #5: Systems Thinking

This product can be prototyped using 3-D printing technology.

It can potentially commercialise with the right partner as suggested above.

There is a standardisation in terms of door dimensions which we can reference from.

Due to the easy installation, it is suitable for anyone.